V8 Turbo. NEW RODS & HEAD STUDS + Project goals !!

I have measured almost every clearance at this moment only the crank axial play and piston ring vertical clearance need to be done

I think did not share any info yet on what the real goals for me are in this project. I changed some idea’s along the way. But i did never mention these things. In the beginning i just wanted to build a S124 with a m113 v8 just with the oem setup so 306HP and a 5 speed auto box.

The second thing was at a turbo to get some more power and a little more technical aspect to the build, I also added the 500E bodykit to the project to make the look more special. Beginning this year i made the change to getting more out of the engine when i run on flexfuel.

The engine will have a base setting on 95 octane fuel what will be around 0.5 bar boost pressure and give around 400hp and 600nm on the crank. this is a quess. when running on E85 i think i can get to 700hp and 900nm at least and i will max out 750hp and 1000nm because i want to run a reliable setup. the transmission can handle 1100nm in stock form but i don’t want to stretch.

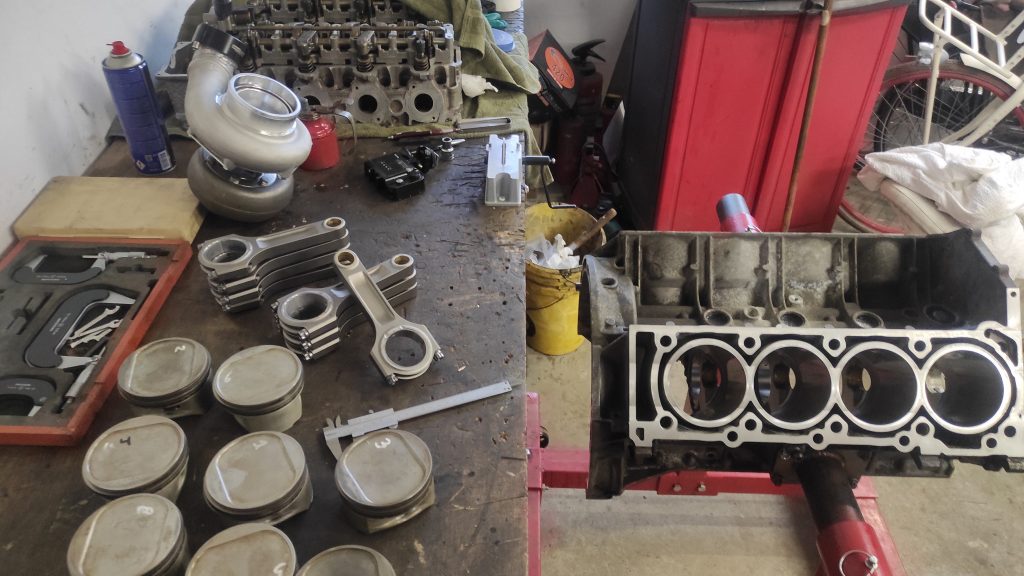

Because of this pushing more out of the engine i think the rods are not strong enough in this 5.0 engine. So i got custom rods made in a I-beam profile with rifle drilling so there is an oil channel to feed oil from the big end to the small end. These rods are rated to 200HP per cylinder. The rods have 3/8″ rod bolts .

I’m also upgrading the headbolts to headstuds. I wanted to go with ARP but ARP is very hard on small quantity. Only other supplier is weistec. But i think these are also ARP. And i’m in Europa and did not want to wait for long delivery times. So through one of my contacts. i got a supplier that could deliver me custom head studs to my specs of lengt and dimension. The have experience with this dimension running then up to 3.0 bar boost pressure. The bolts are rated to have around the same spec as ARP 2000. The dimension will have 7mm more threads down the block and having M11X 1.5 in the block just like oem and on the head side M11X1.25. like same spec as ARP is using.

I have 1 extra set in stock of a connecting rod set. and the will fit in a m113 5.0 and 4.3 and have the oem lenght so keeps the 1:10 CR ratio if the oem pistons are used. if you are interested contact me through the contact page

I can also get extra headstuds set. ask me for pricing

extra info on the oem piston is 56mm high with 2mm flat dome on the head. head thickness at lowest 5,5mm. If somebody has the oem thickness of a m113k piston let me now then we can compare these

if there are any questions just ask

- V8 Turbo. NEW RODS & HEAD STUDS + Project goals !! 4

- V8 Turbo. NEW RODS & HEAD STUDS + Project goals !! 3

- V8 Turbo. NEW RODS & HEAD STUDS + Project goals !! 2

- V8 Turbo. NEW RODS & HEAD STUDS + Project goals !! 1

- V8 Turbo. NEW RODS & HEAD STUDS + Project goals !!